For decades, conventional coatings were the go-to solution for cars and other automobiles. These types of coatings however, can release volatile organic compounds that can seriously impact the environment and in fact the health of the public. As the automotive industry continuously evolved, the need for a less harmful paint grew, which is where powder coating came in.

Unlike other coatings, powder coating does not use or contain solvents. Therefore, when applying it, there is no release of harmful chemicals or emissions into the air. This new solution fast became the number one automotive coating. And it is still the industry standard for a variety of reasons, such as:

- Its application prevents overspray and any excess powder can be re-collected and used again – allowing for more cost-effectiveness.

- It has a faster application process. Therefore automotive companies can deliver a faster turnaround time.

- Powder coating doesn’t drip or run which means that it can offer a uniform finish that is much harder to achieve with other paints.

So How Did It Begin?

In the early 1970s, thin epoxy powders were applied to coil springs for corrosion resistance. The coil springs required protection against the extreme environment they were being used in, but their flexibility couldn’t be compromised.

Once applied, this first type of powder coating allowed for excellent durability and performance from the component. In addition, it also provided resistance against corrosion. Once deemed a success, many types of vehicle components were being powder coated. From steel brackets through to engine blocks and cylinder heads.

Powder coating offered many advantages over liquid coating when it came to automotive parts, including better adhesion and a higher quality finish. It proved to be a highly beneficial and economical solution for car manufacturers. Additionally, it soon began revolutionising the wheel market too. Powder base-coat and clear-coats are still one of the most durable and attractive paint finishes for aluminium wheels today.

Powder Coating Now

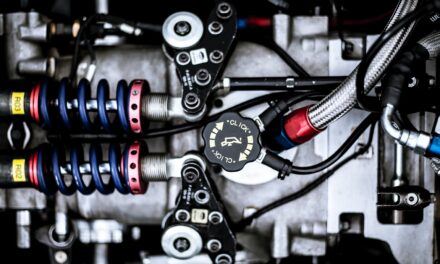

The application process has not changed too much. But, the technology and applications themselves have certainly evolved and expanded over the years. For modern vehicles, there is a requirement for engine compartments to be just as aesthetically pleasing as the exterior or a car. In addition, there is an expectation for fuel injection systems to look much tidier. As a result of these expectations, customer requirements and trends, manufacturers rely on powder coating for its fantastic protective qualities. But additionally, for the flawless decorative finish it can achieve too.

It keeps components looking uniform for many, many miles. Moreover, can hide any imperfections made through the casting process too. Along with the internal engine components, powder coating is also great for the interior and exterior trim parts of an automobile. In fact, the exteriors of a car can often showcase some of the highest quality powder coating applications.

Industrial Powder Coating At R&M Metal Finishing

Here at RM Metal Finishing, we can provide batch and conveyor production coatings to support any automotive powder coating project. We specialise in industrial powder coating services and with our knowledge and experience, so if you are a manufacturer looking to find out more, don’t hesitate to get in touch today.

Explore our website for more information. Or call 01384 266022 to speak to a member of our helpful and friendly team.

If you have found this blog helpful, you may wish to read our previous blog on: What Is “A” Class Powder Coating?