The worldwide reputation of Indestructible Paint’s performance coatings, much of which has been developed in the challenging aerospace sector, is now being applied to the needs of the rail industry. Having recently established a rail department and creating a range of coatings, we have been able to meet the specific needs of rail operators.

Our RW Series of coatings is particularly suitable for this sector with RWIP3000 one of the most recently introduced. Directly applicable to both new build and refurbishment rail procedures, it can offset particular risks. The material is a thin film intumescent coating which, when intumesced, forms a barrier to protect the substrate from burning for a specific number of minutes dependant on thickness. Significantly, when used in conjunction with a heat absorbing primer, RWIP3000 is further suitable for hot areas typically found under a train. For example, around an exhaust area, this will protect cables in the unlikely case of a fire.

Because RWIP3000 performs with a range of substrates, including metals, timber and composites, it is seen as widely relevant to rail design – from vehicle components to civil installations. Suitable for both air- and forced-drying, the coating maintains excellent adhesion – including, importantly for the rail sector, where high air movement is present.

RWIP3000 is normally applied as a primer/sealer intumescent coating which can then be overcoated with a two-component epoxy or polyurethane topcoat – it can be applied either by spray or brush.

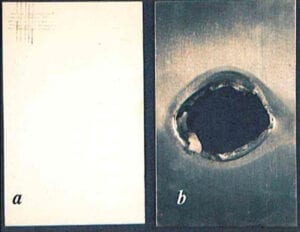

Panel a – coated with RWIP3000 before test. Panel b – identical aluminium panel after 2 minutes flame exposure.

Panel a – showing depth of “char” created after 5 minutes flame exposure

As a clear demonstration of the performance capability of RWIP3000, we have conducted a specific testing operation centred on exposure to an 1100C flame. With the flame positioned 10cm from a 4mm anodised aluminium substrate, the panel condition remained satisfactory, with internal pressure maintained, after a five-minute exposure period. By comparison, over the same period a non-coated panel had distorted and deteriorated before splitting, exploding and completely melting. Similarly, RWIP3000 coating has been shown to maintain heat resistance when exposed to 180°C heat source for more than 100 hours.

We believe these test results clearly demonstrate the suitability of RWIP3000 to the rail industry.

Indestructible Paint have taken the decision to focus heavily on the needs of the rail sector because the challenges presented by our operating environment can be closely aligned to our experience, commitment to research and development and our belief in working closely with customers to develop high performance coating solutions. When allied to our extensive experience in sectors such as aerospace, we are already seeing growing take up of our RW range with RWIP3000 a prime example.

If you would like to find out more about specialist coatings for the rail sector, such as our intumescent coatings, call +44(0)121 702 2485 or email sales@indestructible.co.uk to speak to a member of our helpful and friendly team.