Custom injection moulding is one of the most efficient and effective systems for producing the highest quality plastic goods. Here at Stephens Plastics, we pride ourselves in being the leading injection moulding company in the West Midlands. From concept to completion, our custom plastic injection moulding offers a quick turnaround and optimum performance for all projects. Consequently, injection moulding is the ideal choice for businesses that require mass production.

In this article, we’re going to discuss the injection moulding benefits for high levels of production. Subsequently, you can decide if it’s suitable for your applications and timeframes.

Related: What Are The Advantages And Disadvantages Of Injection Moulding?

Injection Moulding Benefits For Mass Production

Cost-Efficient

First and foremost, we ensure that we offer our customers the best value for money with our custom plastic injection moulding services. We reduce material wastage and guarantee rapid results by using 14 state of the art machines, that only our injecting specialists can operate. Additionally, in combination with computerised control and a matchless monitoring system, we guarantee flawless results.

While prices are determined by your final product’s size, complexity, and features, we always offer competitive rates.

Impeccable Results

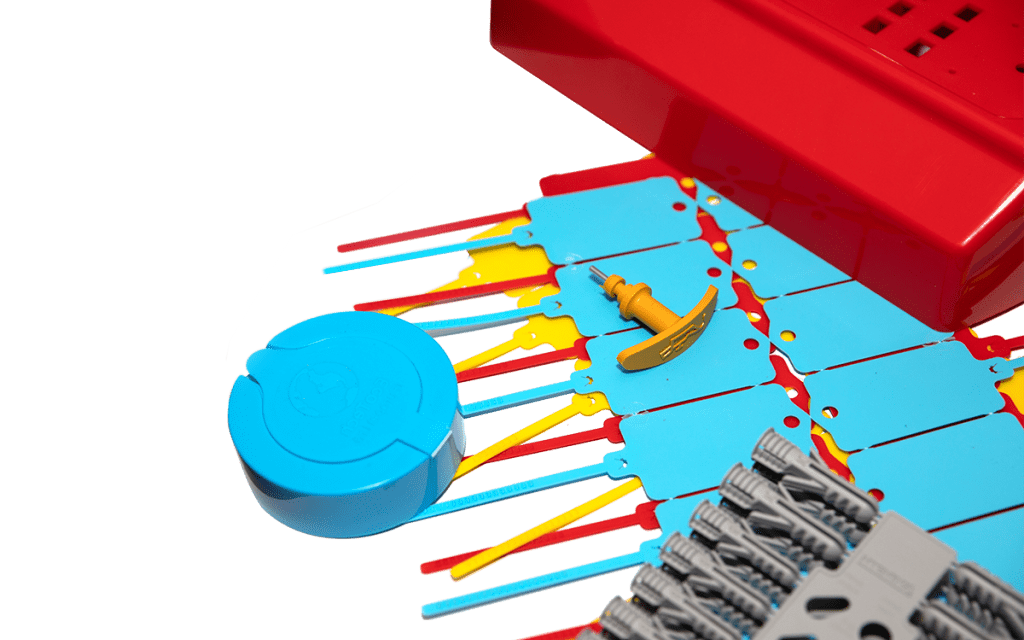

In addition to the plastic injection moulding benefits that our advanced technology attains, we are able to achieve precise and infallible results. We devise original mouldings; therefore, we can meet the needs of all types of projects at all sizes. From 25 ton to 470 ton machinery, we can produce consistent batches of the same product.

Furthermore, you can expect intricate results, accuracy in sizing as well as shape. Also, additional components are all met using the guidelines that will be agreed upon prior to operation. Custom plastic injection moulding is one of the most reliable plastic product manufacturing techniques.

Versatility

We understand that each project requires different materials. This is why custom plastic injection moulding is favourable in a number of industries. For instance, this includes medical, automotive, cosmetics and sports applications. Injection moulds meet all specific requirements, no matter what plastic or characteristics are necessary for completion.

Additionally, we manufacture various types of polymer. Whether you require commodity polypropylene or glass-filled nylons, we have the answer to your project.

Custom Plastic Injection Moulding At Stephens Plastics

In conclusion, plastic injection moulding has many benefits, which allow the demands of small, medium and large quantities. Through an intricate process of designing, construction and tooling, the moulds formed will allow no faults. This means we can quicken the production time immensely. With over 25 years of experience in the custom plastic injection moulding industry, we are pioneers in our field. Through adaptability and the highest level of service, we have had the pleasure of assisting many clients in attaining flawless plastic products. Based in the UK, our plastic injection moulding services are your answer to optimum performance for every project.

Contact us today at sales@stephensplasticmouldings.co.uk or via the phone on 0121 720 9539. We’ll be more than happy to answer any questions or queries you may have on our injection moulding for mass production.

If you found this blogs useful, you may want to take a look at a previous on: What Makes Plastic Injection Moulding So Popular?