There is a long list of hydraulic press uses. A hydraulic press works on the basis of pressure being transferred by compressed fluid. Industries have been using them for years. We, at Workshop Press, constantly improve the designs and continue to evolve and improve their efficiency.

Hydraulic presses are extremely versatile machines. So, with this in mind, you can use them across a range of industries for different manufacturing purposes.

Common Hydraulic Press Uses

Hydraulic presses are very useful for industrial purposes. They have many applications and many industrial environments have uses for them. Hydraulic press uses include sheet metal manufacturing, deep drawing, punching, metal formation, blanking, stamping, molding, forging, clinching, rubber forming, powder compacting (i.e. cosmetics and tablets).

Hydraulic presses all differ in tonnage, the application will determine the tonnage you will need to use.

How does a hydraulic press work?

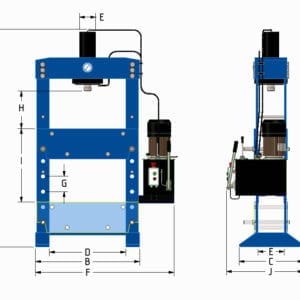

The basic concept for a hydraulic press consists of two connected cylinders. There’s a larger cylinder, known as the Ram, as well as a smaller cylinder known as the Plunger.

The hydraulic fluid is placed in the plunger, then pressure is applied. As the pressure increases, the fluid puts pressure on the piston below, in the larger cylinder. The pressure created between the two cylinders comes into contact with the material, such as metal. It then crushes it to create the product, for example, sheet metal.

Once the desired shape has been fully formed, the pressure on the piston is released and the process starts all over again.

Benefits of a Hydraulic Press

- Consistent tonnage – A hydraulic press can generate full pressing force anywhere in the stroke. This gives you more control over travel distance, pressure, and return position.

- Customisation – Hydraulic presses can be used for even the most complex parts. We can modify a current design, or develop a custom press to meet your specific requirements.

- Small footprint – Hydraulic presses can generate high pressure over a small surface area. This means they take up a lot less footage than many other industry machines.

- Economical – Due to the simplicity of the hydraulic press design they very rarely breakdown, this means less outlay on maintenance. However, should it fail, parts are easy to come by and easy to replace.

- Longer Tool Life – A hydraulic press tool is designed to fit the application, not the press. Overload protection minimises the damage on tooling, thereby extending the tool life.

Hydraulic press uses are in the plenty because they are powerful, adaptable, reliable, and efficient. So, if you think an industrial hydraulic press would be ideal for your working environment, we have hydraulic press machine for sale right for the job.

Head to our website for more information, or call +44 (0)1785 593 088 to speak to a member of our helpful and friendly team. If you have found this blog helpful, you may wish to read our previous blog on Manual Hydraulic Press Basics.