A manual hydraulic press is a staple in the manufacturing industry, due to its versatility and reliability. Since the 1940’s, we have known the impressive power of a workshop press, and its many advantages to those who use them.

What is a manual hydraulic press?

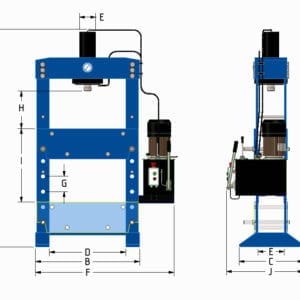

A manual hydraulic press is a device consisting of a hydraulic cylinder, typically fitted in a vertical orientation. This hydraulic cylinder contains a piston that has pressure exerted upon it by the confined oil pressure, generated by a hydraulic pump within the hydraulic system. When the piston advances, due to hydraulic pressure, it produces a compressible force on a stationary baseplate. The hydraulic press is widely used in the metal forming industry, and anywhere that large forces are required.

Hydraulic Press Advantages

There are a variety of uses of a hydraulic press as well as many advantages for using workshop presses.

Simple Design

Hydraulic presses are simple in design, which in turn makes them easy to operate. Plus, the hydraulic press will work effectively for many years if maintained properly. Since there aren’t many moving parts, upkeep is minimal, keeping costs down.

High Volume

A hydraulic workshop press, when properly set up, can be extremely beneficial for high-volume production increasing efficiencies and minimising waste within your facility.

Cost-Cutting

Replacement parts for manual workshop presses typically are not expensive, are easy to find, and are not complex to fix. All components are readily available from RHTC Profi Press, or from a local industrial supply stockist.

More Control

With RHTC Manual Profi Workshop Presses, the ability for multi-action operation, either by hand or by foot, is a huge benefit. This is due to the fact you can eliminate the risk of damaging your machine or tools by readily and accurately being able to control the piston position. You can also control the pressure of the press to suit the job. The ram force, pressure release, the direction and the speed can all be adjusted to suit the requirements of the job.

Smooth Pressing

A workshop press, including a manual hydraulic press, will give you smooth, even pressure throughout the ram stroke. This allows accurate tonnages to be achieved at any point of the ram travel.

Versatile

The possibilities are endless when it comes to using manual workshop presses. This is because they can perform a huge variety of jobs within the tonnage range. Here are just a few examples:

- Bearing pressing

- Press braking

- Metal folding

- Punching

- Broken tool removal

- Forging

- Clinching

- Moulding

- Blanking

- Deep drawing

- Metal forming

All of these processes require precise control and repeatability.

Trust the Experts in Hydraulic Presses

As you can see, there are plenty of advantages to using a manual hydraulic press for industrial purposes due to its simple working mechanism and use of quality components. However, the RHTC manual hydraulic Profi Press has many more benefits to offer.

If you are looking to buy a manual hydraulic press, or would like some more information on one or any other of our metal fabrication equipment, head to our website today. Or, drop us an email to info@workshoppress.co.uk

If you have found this blog helpful, you may wish to read our previous blog on our Metal Punching Machines.