Workshop Presses: Your Trusted Hydraulic Press Supplier in the UK

At Workshop Presses, we’ve supplied hydraulic equipment to leading workshops and factories across the UK for decades. As experts in hydraulic press machines, we’re committed to helping you choose the right solution, understand how it works, and maintain it for long-term value.

Whether you’re a fabricator, engineer, or production manager, this guide is your go-to resource for everything related to workshop hydraulic presses.

What Is a Hydraulic Press Machine?

A hydraulic press machine is a device that uses a hydraulic cylinder to generate a compressive force. These machines are used in pressing, forming, shaping, and assembling materials across manufacturing sectors.

Key industries that rely on them include automotive, aerospace, fabrication, mechanical maintenance, and education.

Benefits of using a hydraulic press machine:

- Powerful and consistent force.

- Versatile in application.

- Lower operating noise compared to mechanical alternatives.

- Precision-controlled pressure.

Types of Hydraulic Press Machines

Choosing the right type depends on your application, workspace, and frequency of use. Here are some popular types available in the UK:

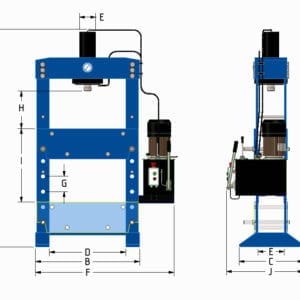

1. H-Frame Press

Sturdy and strong, ideal for heavy-duty applications. Commonly used in industrial fabrication and assembly lines.

2. C-Frame Press

Compact and suitable for medium-duty tasks. Often found in small workshops with limited space.

3. Bench Top Press

Perfect for hobbyists, educators, or small-scale precision tasks.

4. Pneumatic-Hydraulic Hybrid Press

Combines air pressure and hydraulics for enhanced control. Often chosen for repetitive tasks in production environments.

5. Electric-Hydraulic Press

Designed for accuracy, these presses use electric controls for pressure and timing. Useful in labs and electronics assembly.

At Workshop Presses, we supply all of the above with full technical support.

Why Choose a Workshop Hydraulic Press?

If you’re running a UK-based fabrication shop or mechanical workshop, a workshop hydraulic press offers unmatched value. Here’s why:

- Multi-functional: Bend, punch, straighten, and form with one machine.

- Space-efficient: Suitable for tight floor plans.

- Scalable: Ideal for both one-off jobs and batch work.

- Cost-effective: High return on investment due to durability.

What to Look for in a Hydraulic Press Supplier UK

Choosing the right hydraulic press supplier UK can impact productivity, safety, and the long-term value of your investment. Here’s what to consider:

1. Product Range

Does the supplier offer multiple types of presses? Are the machines suitable for your industry?

2. UK-Based Support

A local support team ensures faster response times and reliable servicing.

3. Technical Knowledge

Look for expertise in press operation, parts, and customisation.

4. Warranty and Servicing

A solid warranty and maintenance offering protects your purchase.

5. Customer Reviews

Check for testimonials, case studies, and long-term client relationships.

At Workshop Presses, we meet all five criteria.

Maintenance Needs for Long-Term Use

Routine maintenance extends machine life and maintains pressing precision. Here’s a basic checklist:

- Check fluid levels monthly.

- Inspect hoses and seals for wear.

- Lubricate moving parts.

- Calibrate pressure settings every 6-12 months.

- Schedule annual professional servicing.

Regular care ensures that your hydraulic press machine operates safely and efficiently for years.

Where to Find a Hydraulic Press for Sale in the UK

You can buy a hydraulic press for sale from many sources, but it’s crucial to choose a reputable UK-based supplier.

Workshop Presses offers:

- In-stock models ready for delivery.

- Custom-built machines.

- Full UK mainland coverage.

- Installation and training options.

We also offer site assessments to ensure you select the best solution for your space and tasks.

Why Workshop Presses?

As a long-standing hydraulic press supplier UK, we’ve built our reputation on reliability, service, and quality. Our machines support everything from classroom instruction to industrial production.

We are here to help you make the best investment for your workshop or factory.

FAQs

What’s the difference between a mechanical and hydraulic press?

Hydraulic presses use fluid pressure for smooth, controlled force. Mechanical presses rely on gears and are generally louder and less flexible.

How much space does a workshop hydraulic press need?

This varies by model. Bench-top presses require less than 1m². H-frame presses need around 2m².

Is training needed?

Yes. Basic operational training is essential for safety and efficiency. We provide this with every sale.

Are your machines CE marked?

Absolutely. All Workshop Presses equipment meets UK safety standards and is CE compliant.

What power supply do I need?

Most presses run on single-phase or three-phase electricity. We’ll help you match the right power supply.

Final Thoughts: The Right Press Makes All the Difference

A high-quality hydraulic press machine saves time, reduces effort, and boosts accuracy. From choosing the right model to understanding how to care for it, this guide equips you with expert insight.

Whether you’re looking for a workshop hydraulic press, a custom build, OR a hydraulic press for sale, Workshop Presses has the tools, expertise, and service to support your success.

Contact Workshop Presses today.

Phone: +44 (0)800 999 1090

Email: info@workshoppress.co.uk

To read the original article please see here