“While manufacturing and processing operations are, understandably, under the spotlight during the current situation, there are many areas where they make an essential contribution to meeting the challenges we all face – and the ongoing supply of protective and performance coatings is a clear example,” states Brian Norton, Managing Director of Indestructible Paint Ltd. Traditionally, our products fulfil a range of operational needs in specific environments – from aerospace and the military to power generation – and, today, many remain central to the provision of essential services. “Consequently we, and others in our industry, have adapted our services and facilities to match new requirements,” he adds.

“The application of performance critical coatings – often providing properties that include low friction or heat resistance – can be central to repair and maintenance procedures,” continues Brian Norton. “For example, operations such as casualty evacuation (CASEVAC) can be dependent on reliable and safe helicopter usage, while maintaining power supplies to key institutions like hospitals has, perhaps, never been more important. In all cases, maintenance and repair are key factors and these are often closely linked to coating performance.” As a result, he says, manufacturers in the sector are concentrating their efforts on ensuring not only that supplies are maintained but, where needed, research and development into new coating technologies also continues.

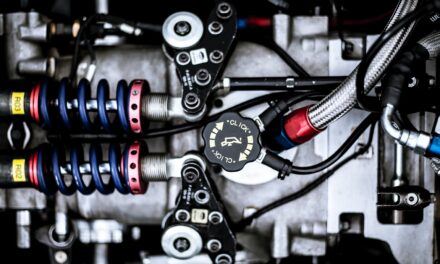

A typical testing operation at Indestructible Paint

“Many of our customers, such as those in aviation component manufacturing, are among the leading and largest in their respective fields so it is vital that we continue to meet the high standards of quality that they demand,” points out Brian Norton. “Performance and safety are as important now as they ever were.”

Indestructible Paint’s Birmingham-based facility has been adapted to meet these new challenges. For example we are continuing our laboratory, production and despatch operations while instigating the stringent distancing and handling measures specified by government guidelines.

“We have even brought in new specialist equipment to enable us to provide an in-house service to spray-coat propellers that are a crucial part of light aviation and larger MOD aircraft maintenance and repair operations. These can impact directly on a number of areas, from international cargo transportation to the maintenance of air ambulance services,” adds Brian Norton.

Spray Coating Application of Propellers at Indestructible Paint’s Facility

Indestructible Paint believes this also reflects on an innovative response to both new and reshaped supply chain requirements in both our UK and worldwide markets. Continuing demand for our products and services is demonstrated by our sustained exports to some 20 countries – indeed, sales in April this year are still 80% of those in the same month in 2019.

Our organisation holds daily Senior Management Team meetings to ensure operations are optimised and we are happy to report that, to date, there has been no need to furlough staff.

“We are clearly living in unusual times and it is notable how much of industry contributes to the vast range of operations that are vital in this context,” concludes Brian Norton. “The ability of business to react to these new needs – and, vitally, the ongoing commitment of the individuals within them – can only underscore the determination to overcome the situation that we all currently face.”