If you are looking for curing oven replacement services then look no further than td finishing. We are one of the country’s leading installers of powder coating systems. Our team specialises in providing a wide range of coating equipment for all sorts of different businesses. Whether you are looking for a powder coating oven, or the installation of a brand new powder coating plant, we are on hand to provide you with the best solution. We can accommodate many different requests, but we are also on hand to replace faulty or ageing equipment too.

Installing powder coating equipment

We have provided curing oven replacements for many clients in different circumstances. For example, one of our clients decided to replace their equipment following a very serious flood last winter.

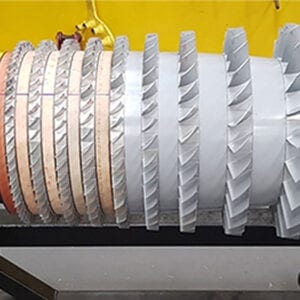

The first steps were to replace the powder booth and curing oven. The original plant was utilising an off-line camel back oven. This required additional manual intervention during the coating process. As well as serious inefficiencies, the process was introducing risks to the final finish of the product. These risks were mainly arising from the additional handling of the coated items before curing.

The first steps were to replace the powder booth and curing oven. The original plant was utilising an off-line camel back oven. This required additional manual intervention during the coating process. As well as serious inefficiencies, the process was introducing risks to the final finish of the product. These risks were mainly arising from the additional handling of the coated items before curing.

There are many advantages to online powder coating. However, the main benefit is the lack of mechanical intervention once placed on the line. The new conveyorised powder coating oven has been built off-line and a new track extension has been installed.

This allowed for only a very short break in production when the new section of track was connected in to the original. As well as being more modern, efficient and safer, the optional internal stainless-steel finish improves the aesthetic of the oven as well as ensuring its longevity.

Dying oven replacements

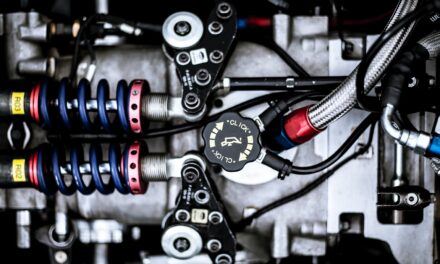

The client was then needing to replace the drying oven. At the same time, they were also working through a busy period of production. As a result, the task was trickier as the existing oven was on-line and still in use. We also needed to make sure that we were keeping down times as low as possible. This meant installing the replacement oven within a very short window.

The client shut the factory for 11 days, allowing us to remove the existing drying oven and install the new system without fault. The drying oven, like the curing oven was supplied with efficient, modern fans and gas burner. We also supplied the modulating gas burner with an up to date controller unit. The modulating gas burners allow us to modify the existing control panel and upgrade from the original hi/low burner type on the old oven. The ovens are now commissioned and up and running with enhanced performance, reduced waste and energy usage.

Contact us today

If you would like to find out more about powder coating systems, head to our website today. Alternatively, call 0121 520 8884 or email andrew@tdfinishing.co.uk to speak to a member of our helpful and friendly team.

If you enjoyed reading this article you may also like to read our previous post on pretreatment systems.