New two pass minute powder curing oven | After the successful phase 1 pretreatment project, td finishing has recently completed the phase 2 installation at the UK’s leading shelving and racking manufacturers site in Milton Keynes.

Again, with close liaison with the clients project manager, the contract was complete on time, to budget and with no unplanned production downtime.

The project included the dismantling of the existing infra red pre gel oven, curing oven and monorail conveyor. The dismantling of the existing equipment was completed in a 3 day period where engineers worked around the clock to ensure the site programme was achieved.

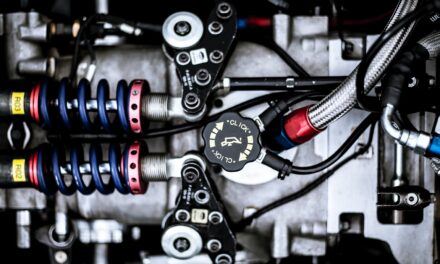

Before the dismantling was completed, installation of the new two pass minute powder curing oven commenced maximising installation time and making sure production would recommence on programme. The new oven design utilised three direct gas fired heater units complete with modulating gas burners, td’s purpose manufactured insulated oven panels and an air distribution and recirculating system to enable 4.2m long racking uprights to be processed.

The F8 monorail conveyor circuit upgrade was completed during this phase and incorporated a new dual drive system, track, chain and an upgraded flight bar design.

The completed plant with the addition of the clients unique automatic unloading mechanism gives the ability to operate at speeds up to 3300mm per and have an oven time of 18mins ensuring all powders can be fully cured.

All the latest Manufacturing News brought to you by AIM Internet.

AIM Internet specialise in digital marketing services that provide strategic online marketing solutions to grow your business. Contact us today to find out more.