KUKA initiated a tiered system partner programme to establish strategic partnerships intended to bring in-depth knowledge of automated applications, and specialist industry skills to the benefit of customers across all UK manufacturing sectors.

CNC Robotics has become an integral member of the KUKA programme, and a thought leader within the partner framework that is now well established and growing. The diverse partner portfolio of silver, gold and platinum partners brings to the table specialist skills, and knowledge, in all market sectors, for customers requiring automated equipment integration, strengthening the breadth and depth of expertise KUKA can make available to its customers. Once again, as Platinum system partners, KUKA UK is delighted to renew this strategic partnership with CNC into its eleventh year.

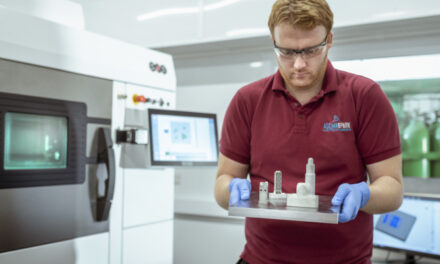

It’s often a big step for companies (especially those new to automation) to commit to a robotic based system. Significant considerations, such as cost, capability and reliability are key deciding factors that must be substantiated prior to any financial commitment. CNC Robotics are pioneers, championing the use of industrial robots as an alternative to traditional manufacturing tools, with a focus on improving productivity and implementing operational resilience for customers.

Substantial challenges have been felt within UK manufacturing over the course of the last two years, with ever niche and diverse applications coming to the fore as manufacturers contend with depleting skilled labour pools and increases in demand not seen before. Such challenges are met with a passion for problem-solving, by the CNC team.

“CNC Robotics was born out of the need for a low-cost machining solution for scenic construction. When Jason couldn’t find anything suitable, he developed a unique robotic system that could create large-scale props in intricate detail. He quickly saw the potential for using robotics as milling machines in industries that needed a cost-effective tool for large-scale machining. Over the next two years, the sale of robots for manufacturing became so successful that it took over the set-building business, so CNC Robotics was born. KUKA has robots have been at the core of our offering due to the team’s customer-centric approach, and intelligent and innovative solutions” – Philippa Glover, Managing Director.

One of just six Platinum partners, CNC Robotics has a firm grasp on the characteristics of the KUKA hardware, periphery and capabilities, so is fully conversant across the vast KUKA portfolio. Going through an evolution of sorts of its own, the CNC brand is growing and developing a portfolio of standard operating and training cells that it hopes to roll out across industry, with the iconic KUKA robot at its core, helping UK manufacturing to achieve automation excellence.

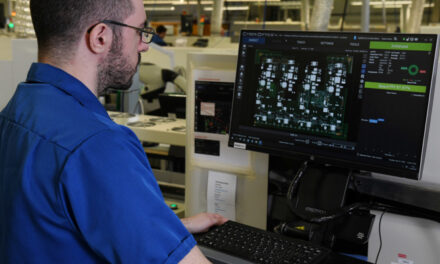

The Liverpool-based firm specialises in tackling the most demanding challenges; even inventing ad-hoc processes that utilise robotics and automation in very novel ways, keeping their customers, at the leading edge of technology, as consumer demand necessitates huge increases in throughput and process optimisation initiatives, using robots.

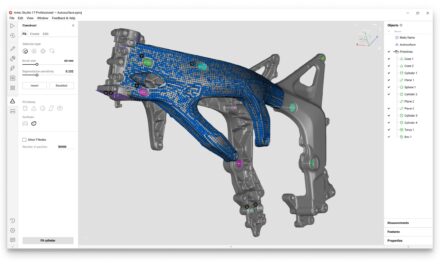

CNC Robotics has pioneered the use of industrial robots as an alternative to traditional machine tools

CNC Robotics’ passion for innovation and expertise makes them market leaders in robotic integration and also robotic systems in the UK, across a variety of manufacturing applications.

“The collaborative expertise that KUKA and CNC Robotics can deliver, opens doors to potential customers which are ultimately our combined goal for lasting commercial relations,” said Bernard Bagley, Head of Robot Sales (GI) UK. Continuing, “Bespoke engineering can be expensive, but the KUKA/CNC partnership dictates we can provide our customers with a better solution at a more favourable cost.

CNC prides itself on the delivery of advanced manufacturing solutions, and industry partnerships such as this, are crucial to our success. Having once again secured their accreditation as a KUKA Platinum System Partner, CNC continues to contribute highly advanced engineering systems across multiple projects, supporting customers’ advanced manufacturing ambitions, in a competitive marketplace”.

“Rather than producing parts by hand or investing in a large, heavy traditional style machine, manufacturers are starting to look towards CNC Robotics and our robotic machining cells due to the attractive ROI offered to manufacturers who aren’t chasing micron precision accuracy.” Philippa Glover, Managing Director.

Current industry trends dictate that there shall likely be no let-up in the demand for robot process automation, as manufacturers realise the benefits that can be achieved. As opportunities become available to support productivity, partners such as CNC shall be on hand, to impart their automated systems wisdom, and deliver automation excellence across industry.

CNC Robotics’ technical foundations are built on the company’s ability to drive robots accurately with software specifically for subtractive and additive applications.